Feed mill mixing tends to be one of the most expensive and time-consuming aspects of running a feed mill. Combining all your source ingredients into a consistent, nutritious product can be a challenge, especially if you’re using the wrong equipment. There are several things you can do to reduce mixing time without sacrificing the overall quality of your products.

Use these tips to streamline the feed mixing process as much as possible.

Proper Sequencing

Nothing will slow down the feed mixing process like poor or improper sequencing. Every recipe comes with its own considerations. You need to decide if it’s better to grind up your source materials before mixing them together, or vice-versa. Grinding up your product ahead of time can simplify the mixing process, but you’ll need to store your source ingredients temporarily until you mix them together.

Grinding up your ingredients after they’ve been mixed together can simplify the grinding process, but you may have trouble getting a proper mix. Larger, coarse particles may stick together and sink to the bottom as lighter particles float to the top, impeding the segregation process. Consider changing the sequence of your recipes to improve efficiency.

Accurate, Consistent Grinding

If you choose to grind your ingredients before mixing them together, you need to make sure these particles are uniform in size. If these particles are uneven, you will have more trouble separating them out during the mixing process. They may clump together or sink to the bottom, resulting in an uneven mix.

Inspect your source ingredients to make sure they are uniform in size before moving on to the mixing phase. If they appear too large or too coarse, run them through the grinder again until they are even in size. Maintain your grinding equipment to make sure it is working properly.

The Buhler Multi-Impact Hammermill is designed for efficient grinding. The machine bounces the particles around inside the grinding chamber so that they hit the cutting blades more than once. This ensures that every particle is the same size before passing through the screen.

Adding Liquids

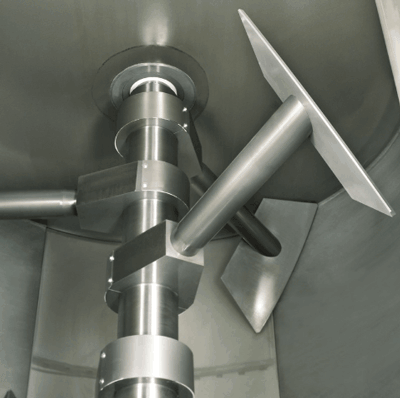

Adding fluids and liquids to your mix can also complicate the process. It’s best to maintain constant access to the mixing chamber so you can add liquid continuously. Use the Buhler Speedmixer to simplify the feed mixing process. It comes with an opening at the top that lets you slide a nozzle into the mixing chamber while the machine is running. You can quickly spray down the mixture as the blades keep turning, so you can coat every particle in just 20 seconds or less.

Efficient Cleaning and Maintenance

Regularly clean and inspect your grinding and mixing equipment to speed up the process. If your blades are dirty or filled with residue from previous batches, wipe them down before loading in more of your product. This will help you keep your equipment running for the foreseeable future, so you don’t have to worry as much about delays and downtime.

The Buhler Speedmixer is the latest in feed mill technology and allows you to walk into the chamber, helping you clean the interior in record time.

Contact the professionals at Halverson Company to learn more about the feed mill construction process.