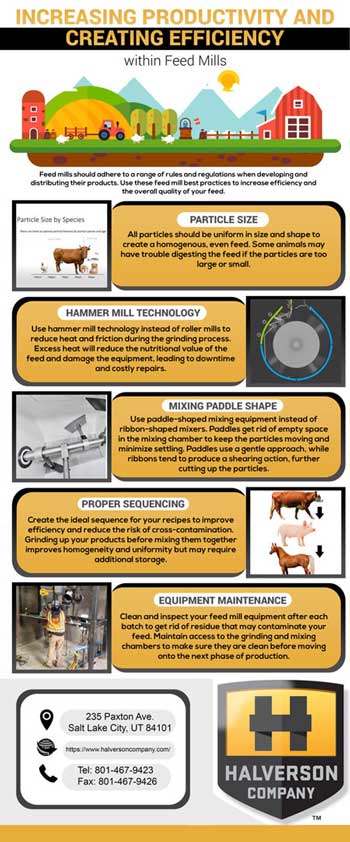

Feed mills should adhere to a range of rules and regulations when developing and distributing their products. Use these feed mill best practices to increase efficiency and the overall quality of your feed.

Particle Size

All particles should be uniform in size and shape to create a homogenous, even feed. Some animals may have trouble digesting the feed if the particles are too large or small.

Hammer Mill Technology

Use hammer mill technology instead of roller mills to reduce heat and friction during the grinding process. Excess heat will reduce the nutritional value of the feed and damage the equipment, leading to downtime and costly repairs.

Mixing Paddle Shape

Use paddle-shaped mixing equipment instead of ribbon-shaped mixers. Paddles get rid of empty space in the mixing chamber to keep the particles moving and minimize settling. Paddles use a gentle approach, while ribbons tend to produce a shearing action, further cutting up the particles.

Proper Sequencing

Create the ideal sequence for your recipes to improve efficiency and reduce the risk of cross-contamination. Grinding up your products before mixing them together improves homogeneity and uniformity but may require additional storage.

Equipment Maintenance

Clean and inspect your feed mill equipment after each batch to get rid of residue that may contaminate your feed. Maintain access to the grinding and mixing chambers to make sure they are clean before moving onto the next phase of production.

Halverson Contact Info & Logo

235 Paxton Ave.

Salt Lake City, UT 84101

https://www.halversoncompany.com/

Tel: 801-467-9423

Fax: 801-467-9426